XGN-12(TT) Model Solid-Insulated Switchgear

introduction

XGN-12(TT), as a key part of the automatic power distribution

system, is a type of intelligent and eco-friendly switchgear. The

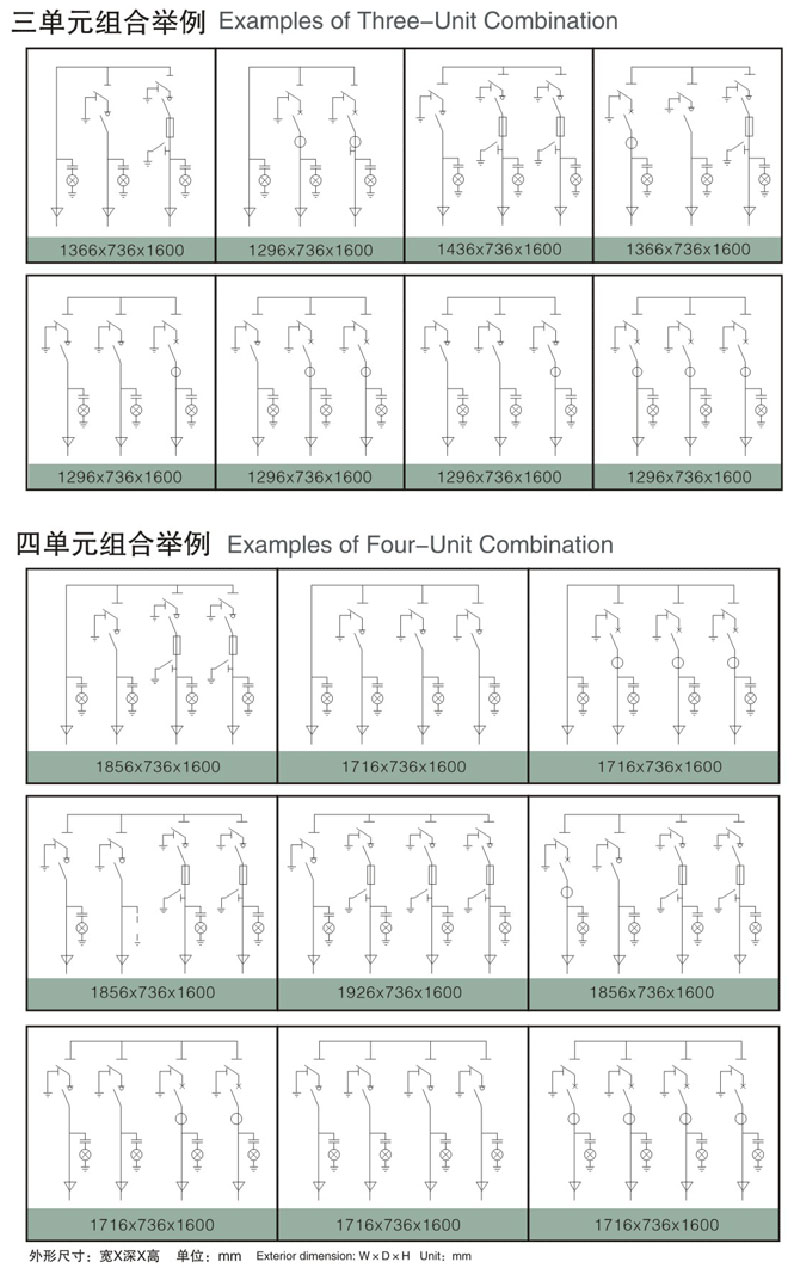

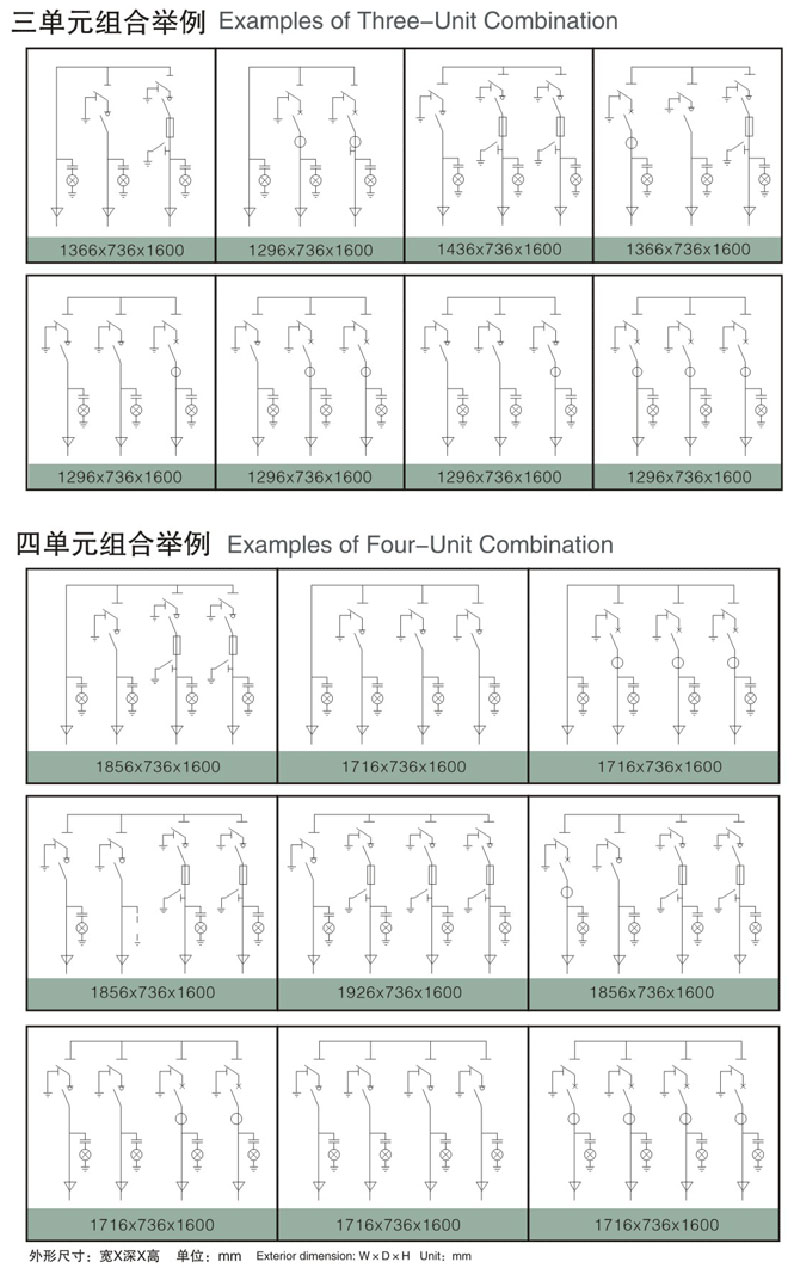

XGN-12(TT) type switchgear composes of three functional units, unit

V (circuit breaker unit), unit C (load switch unit) and unit F

(combined electric apparatus unit). When the system is required to

be equipped with multiple units, it can be extended freely on both

right and left sides, and arranged at random in accordance with

different design schemes, thus satisfying different requirements

for configuration.

Structurally, each unit consists of the instrument chamber, the

operating mechanism and the primary circuit. The instrument chamber

can be provided with microprocessor-based protection and other

meters and gauges; the operating mechanism is a mechanism designed

exclusively for spring operating, and if required, an electric

operating mechanism can be equipped additionally; the primary

circuit features its automatic pressure gelation (APG) process,

through which the busbar, isolating switch and arc extinguish

chamber are totally enclosed in epoxy resin together, with the

busbar connected with a special-purpose connector.

With its advantage of compact structure, full insulation, long

service life, maintenance-free, less space occupation, good safety

& reliability, and being free from environmental impact, the

XGN-12(TT) type solid-insulated switchgear is widely applied to

power supply to industrial and civil ring networks and terminals,

specially to smaller secondary substations, switching stations,

industrial and mining establishments, airports, railways,

Environmental Conditions for Product Use

- Sea Level Elevation: ≤5000m

- Ambient Temperature: -45℃~45℃

- Mean daily Max. temperature: +40℃, mean yearly Max.

temperature: +35℃

- Wind velocity: not higher than 34m/s

- Relative Humidity: ≤95%(+25℃)

- Ground inclination: ≤5℃

- Earthquake Intensity: NMT 8 Degree

- Equipment should be installed at places free from fire,

explosion hazard, chemical

corrosion and violent vibration.

Features

Excellent Performance of Epoxy Resin

The XGN-12(TT) type solid-insulated totally enclosed switchgear

is produced from the special epoxy resin as insulating material.

This type of epoxy resin boasts its

excellent performance:

Excellent electric insulation property

Dielectric strength:20~30KV/mm

Volume resistivity:(ρv)1×1013~15Ω.m

Dielectric loss angle tangent:(tgδ)<0.004(50Hz)

1. Able to endure a heat as high as above 200℃, and to keep a

good insulation property even at a high level of temperature;

2. Stable chemical property: excellent resistance to alkali, acid

and solvent, as well as good resistance to temperature aging and

radiation aging;

3. With a coefficient of thermal conductivity of

80×10-2~100×10-2W/m.k, it contributes to heat dispersion;

4. Having strong cohesion for any substances, close molecular

structure and high mechanical strength, it plays a protective role

for switchgears.

5. With a curing shrinkage as low as 1%~2% generally and a

coefficient of liner expansion as low as 6×10-5/℃ generally, it

allows switches to have a stable dimension

and a small internal stress for fear of a cleavage in any

circumstances.

Green Switchgears Beneficial to Environmental Protection

Unique Structure

1. An electric operating mechanism is optional not only for the

main switch but also for the isolating switch and ground switch, as

is a profound backup for the automation

and intelligentization of the electric distribution network;

2. The totally sealed design of live parts allows an integral

realization of the fully insulated and totally sealed structure,

with a degree of protection of IP67, which means

the unit can function normally for a short time even under water.

3. The open/close positions of switches can be seen clearly from

the sight glass;

4. The modular design with segregated phases facilitates

combination of units and expansion of loops, and enhances

insulating property.

5. An absolute eco-friendly structure, with no SF6 being used for

gas insulation and free from pollution forever;

6. The ingenious design of mechanical and electric interlocks can

meet the requirements for the ?five preventions? , thus ensuring

the safety of personnel and equipment;

The delicate outline and pastel shades bring users a sensuous

enjoyment.

Perfect Safety Performance

1. The disuse of SF6 in the solid-insulated switchgear avoids any

explosive accidents arising from deterioration in insulating

property and arc-extinguishing capability, which is attributable to

insufficient gas pressure in the SF6 ring network cabinet.

2. The adoption of an explosion-proofing vacuum arc-extinguishing

chamber, in which the solid insulating layer provides the switch

with further protection, ensures the safety of equipment and

personnel.

3. The modular design of the segregated structure between phases

avoids any accidents arising from short circuit between phases or

between multiple loops.

4. The “five-prevention interlock” between the main circuit

switch, isolating switch, ground switch and cabinet door ensures

the safety of repairmen and maintenance personnel.

5. The open/close positions of all phases of switches can be seen

clearly from the sight glass, thus enhancing the safety of

personnel during operation, examination and repair.

6. The high glass temperature of epoxy resin guarantees that the

insulating property of epoxy resin and silicon rubber would not

deteriorate when suffering a high temperature.

7. The adoption of flexible fillers between the epoxy resin

insulating layer and the primary conductor of switches eliminates

the stress caused by expansion with heat and contraction with cold,

thus avoiding the occurrence of cracks.

8. The adoption of all-round reversing gear with the operating

mechanism improves the reliability of the operating mechanism.

9. A degree of protection as high as IP67 allows the

solid-insulated switch to function normally even under water.

10. The switch position indication is fixed to the main shaft,

thus enhancing the correctness of the indication.

Technical Data